Some 20 percent of the protein consumed around the world today comes from seafood, a nutritionally dense food source that does quick work satisfying hunger. And the appetite for seafood, especially fish, will likely only continue to grow.

But the soaring demand for fish is putting strain on fish populations and on the seafood industry, which is already struggling to keep up with demand.

“More than three billion people depend on the ocean and its surroundings for their living,” says Daphna Heffetz, CEO of the Israeli food-tech startup Wanda Fish. “Marine biodiversity is critical to the survival of people and our planet. But overfishing, as well as water pollution, is damaging the vast and vital ocean ecosystem. Many wild fish populations are sadly in decline.”

To right this imbalance, Heffetz and Wanda Fish, which launched in 2021, have joined the rapidly expanding “alt protein” scene, also known as cellular agriculture.

Here, cultivated meat—that is, meat grown directly from animal cells, with taste and texture not unlike those of meat from animals bred on farms or fished from the sea—provides an alternative source of protein to help advance food sustainability, nutrition, and security.

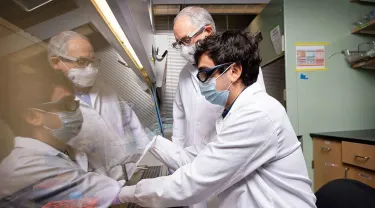

For help in developing and refining this technology, Wanda Fish turned to a leading expert in the burgeoning field of cellular agriculture: Tufts' David Kaplan.

Kaplan, the Stern Family Professor of Engineering and chair of the Department of Biomedical Engineering, is a renowned researcher in cellular agriculture. For years, he and his group have led this field in devising novel means of approximating the characteristics of “real” meat through tissue engineering.

He is also the recipient of U.S. Department of Agriculture funding to establish the first national center in the U.S. dedicated to research in cellular agriculture.

In 2021, Kaplan’s work developing fish cell cultivation attracted the attention of Wanda Fish, who saw in it a means to address the growing demand for seafood, and especially for fish. The company has now licensed the technology and, for the next two years, is sponsoring Kaplan’s research into cellular agriculture-based production of fish tissue.

Kaplan describes how it works: “We start with a single, one-time sample of a real native fish muscle and fat tissues,” he says. “We then pursue the replication of the biological growth of fish, with the nutritional attributes, including protein and omega 3 content, as well as the flavor and textural properties. What we avoid are the microplastic, mercury, or other chemical toxicities that have been commonly found in some of the wild catch.”

Heffetz says her company has already made headway in developing its first prototype of a fish fillet directly from fish cells.

“Our platform includes animal-free growing medium, know-how in producing native muscle and fat tissues, and specially customized bioreactors that will give us the capacity to scale up production and eventually bring our cultured fish products to cost parity with conventionally fished counterparts,” she says.

The progress she describes moves the company ever closer to its goal of providing a means to produce sustainable, flavorful fillets for a variety of species, so it can satisfy a spectrum of consumer preferences—all without placing any burden on the ocean and the extraordinary universe of life within it.