In cellular agriculture—the production of meat from cells grown in bioreactors rather than harvested from farm animals—growth factors bind to receptors on the surface of cells and provide a signal for the cells to grow and differentiate.

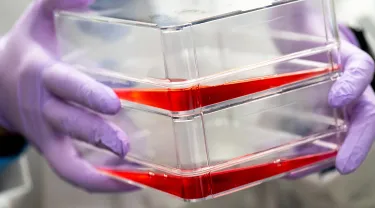

Until recently, growth factors had to be added to the liquid, or media, surrounding the cells. Made from recombinant protein and sold by industrial suppliers, growth factors contribute to a majority of the cost of production for cultivated meat—up to or above 90%.

Since the growth factors don’t last long in the cell culture media, they also must be replenished every few days. This limits the ability to provide an affordable product to consumers. Taking that ingredient out of the growth media leads to enormous cost savings.

At the Tufts University Center for Cellular Agriculture (TUCCA), led by David Kaplan, Stern Family Professor of Engineering, researchers have developed new technology that allows for that cost savings: they created bovine (beef) muscle cells that produce their own growth factors.

To do so, they modified stem cells to produce their own fibroblast growth factor (FGF), which triggers growth of skeletal muscle cells—the kind one finds in a steak or hamburger.

“FGF is not exactly a nutrient,” explained Andrew Stout, who was at the time lead researcher on the project and is now director of science at Tufts Cellular Agriculture Commercialization Lab, which is a new Tufts initiative with the goal of commercializing technologies to solve cost and scale bottlenecks within the field of cellular agriculture.

“It’s more like an instruction for the cells to behave in a certain way,” said Stout. “What we did was engineer bovine muscle stem cells to produce these growth factors and turn on the signaling pathways themselves.”

While the researchers’ work significantly cuts the cost of media, slower growth did occur with the engineered cells—but Stout said that issue can be overcome. Strategies for tackling it could include changing the level and timing of expression of FGF in the cell or altering other cell growth pathways.

Exploring such strategies—and optimizing growth factors to apply to a range of meats in addition to beef, such as chicken, pork, and fish—will lead to further advances, Stout said, making it likely that affordable cultivated meat will be available in local supermarkets within the next few years.