Researchers at Tufts University, along with colleagues at three other universities, have demonstrated that a catalyst can indeed be an agent of change, including when it comes to the environment.

They used quantum chemical simulations run on supercomputers to predict a new catalyst architecture as well as its interactions with certain chemicals and demonstrated in practice its ability to produce propylene—which is in short supply but critically needed in the manufacture of plastics, fabrics, and other chemicals. The improvements have potential for highly efficient, “greener” chemistry with a lower carbon footprint.

The demand for propylene is about 100 million metric tons per year (worth about $200 billion), and there is simply not enough available to meet surging demand. The most common method for producing propylene and ethylene is steam cracking, which has a yield limited to 85% and is one of the most energy-intensive processes in the chemical industry.

What’s more, the traditional raw materials for producing propylene are by-products from oil and gas operations, but the shift to shale gas has limited its production. Typical catalysts used in the production of propylene from propane found in shale gas are made up of combinations of metals that can have a random, complex structure at the atomic level. The reactive atoms are usually clustered together in many different ways, making it difficult to design new catalysts for reactions.

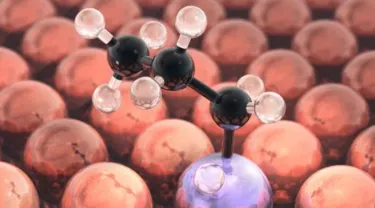

By contrast, single-atom alloy catalysts—first discovered by Tufts researchers—disperse single reactive metal atoms in a more inert catalyst surface, at a density of about 1 reactive atom to 100 inert atoms. This enables a well-defined interaction between a single catalytic atom and the chemical being processed without being compounded by extraneous interactions with other reactive metals nearby.

Reactions catalyzed by single-atom alloys tend to be predictable by theoretical methods; they also tend to run more efficiently and under milder conditions and lower temperatures and thus require less energy to run than conventional catalysts. Such enhancements promote more environmentally friendly chemistry with fewer emissions.

Charles Sykes, John Wade Professor in the Chemistry Department at the Tufts School of Arts and Sciences, was corresponding author of the study and conducted this work in collaboration with colleagues at University College London, Cambridge University, and the University of California, Santa Barbara.