Sustainable Materials

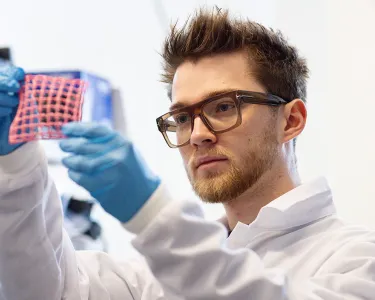

Scientists and engineers across disciplines at Tufts are at work on the development of materials with unprecedented functional properties—and countless applications. Of particular note: Researchers at Tufts’ Silklab are creating “living materials” at the intersection of biology and technology, opening doors to novel advances in medicine, sustainability, and much more.

Reimagining Substances for Advanced Technology, Global Health, and the Planet’s Future

Tufts researchers are at the forefront of technology development, applying lessons from biology, chemistry, engineering, and more to improve existing materials or compose entirely new ones. Many of these new materials represent breakthroughs with the promise of reducing our environmental impact and greatly improving the quality of life for people worldwide.

As one example of a significant advance at Tufts: the advance toward safer drinking water promises by a filtering method that leverages new synthetic polymer membranes that mimic the highly selective properties of biological cell membranes.

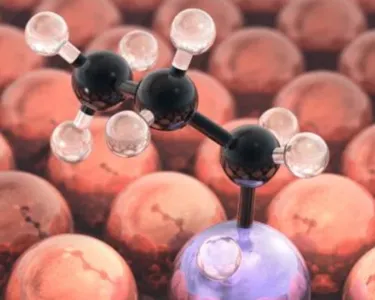

Consider also: Tufts chemists are using quantum chemical simulations to predict a new catalyst architecture as well as its interactions with certain chemicals in service of producing propylene—which is in short supply but critically needed in the manufacture of plastics and fabrics. The improvements have potential for highly efficient, “greener” chemistry with a lower carbon footprint.

Specifically in the field of silk and other naturally derived substances that minimize the use of toxic chemicals, Fiorenzo Omenetto, Doble Professor of Engineering and director of Tufts’ Silklab, is at work with his colleagues and undergraduate and graduate student researchers to create innovative materials with the potential to revolutionize manufacturing, medicine, and other fields.

In addition, silk has the potential to revolutionize sustainable material processing, and manufacturing silk can be used to produce a leather-like material through a water-based and energy-saving process that—unlike other “fake leather” materials—requires only mild chemicals and creates mostly nontoxic waste. The resulting products are strong, soft, pliable, and durable, and, like natural leather, they are biodegradable once they enter the waste stream.

Exploring the use of silk for such manufacturing purposes positions Silklab to open up new opportunities for sustainability that can help preserve our planet.

What’s it like to be a student at the forefront of the future? In this video, hear from IDoc PhD students as they share their experiences working in Silklab alongside Doble Professor Fio Omenetto, and discover how this "caterpillar of wonder" is forging a new pathway in materials science.

Selected Research

Additional Uses for Silk Fibroin

-

Food Protection

An edible, transparent, tasteless film of silk that keeps moisture in or out and holds pathogens at bay can increase the shelf life of foods, reducing food waste and helping food go further to sustain a burgeoning population.

-

Nontoxic Glue

By replicating key features of the adhesives mussels and barnacles produce, silk fibroin can be used to create a powerful glue that sets and works as well underwater as it does in dry conditions and is stronger than most synthetic glue products on the market.

-

Nonstick Surfaces

Silk has been used to create a nonstick, water-repellent surface that can be used in cookware, for medical applications, on metals to help prevent rust, or on fabrics to make them easier to clean.

-

Biopolymer Sensors

Sensors that can be printed like ink on wearable items such as gloves, masks, or everyday clothing to warn people of bacteria, toxins, and dangerous chemicals in the environment by glowing when it detects otherwise invisible threats.